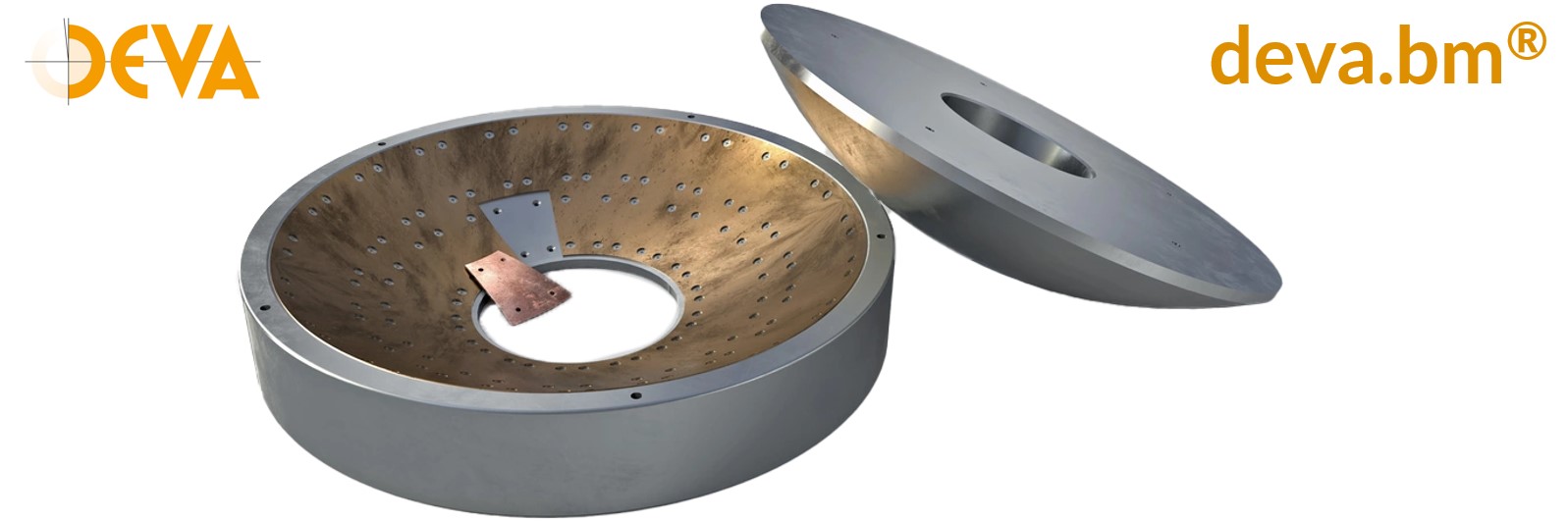

Metal based backing with deva.metal sliding layer

deva.bm® is a thin-walled self-lubricating composite sliding material. It consists of a backing made of standard steel, stainless steel or bronze with a deva.metal® layer applied in a combined rolling/ sintering process.

deva.bm® is a high performance material that offers basically the same bearing characteristics as deva.metal, but is capable of handling even higher loads and provides an economic solution to many bearing problems.

- Suitable for dry running at slow sliding speeds and high loads

- Stick-slip free

- High resistance to temperature and corrosion

- High static and dynamic load-bearing capacity

- Maintenance free

- Economic solution

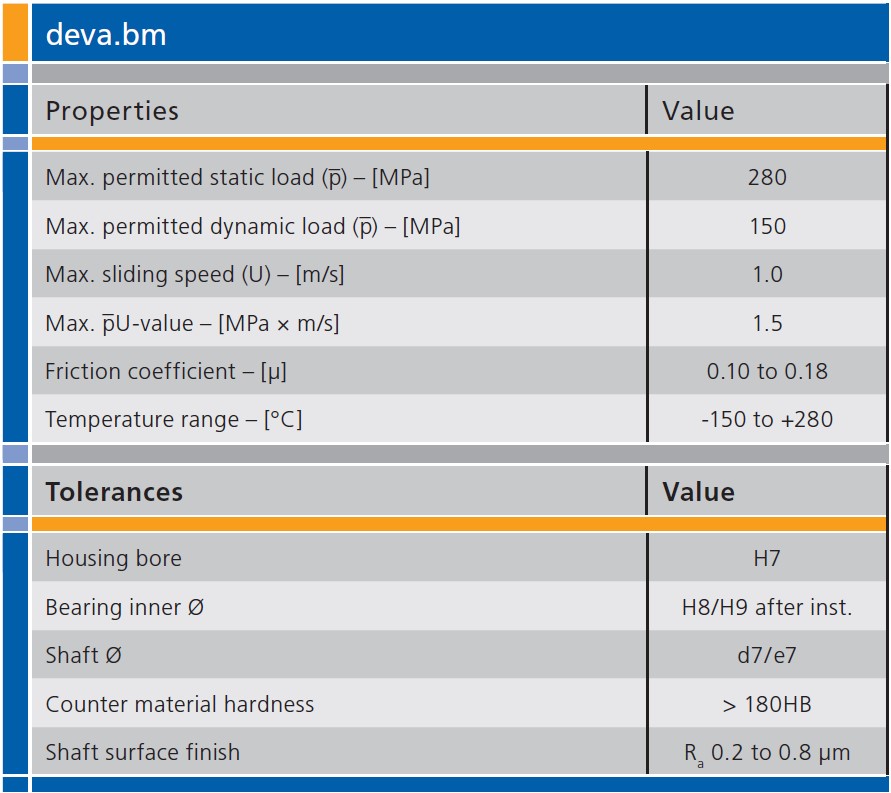

- Material properties

deva.bm® is a self-lubricating composite bearing material, comprising a steel backing with a sliding layer of deva.metal®. deva.bm is produced using a special sintering process and usable in/at:

- Dusty environments

- Temperatures ranging from -190 °C to +280 °C.

- Corrosive environments & Seawater.

(Does not absorb water and guarantees maximum dimensional accuracy. - Radioactive environments.

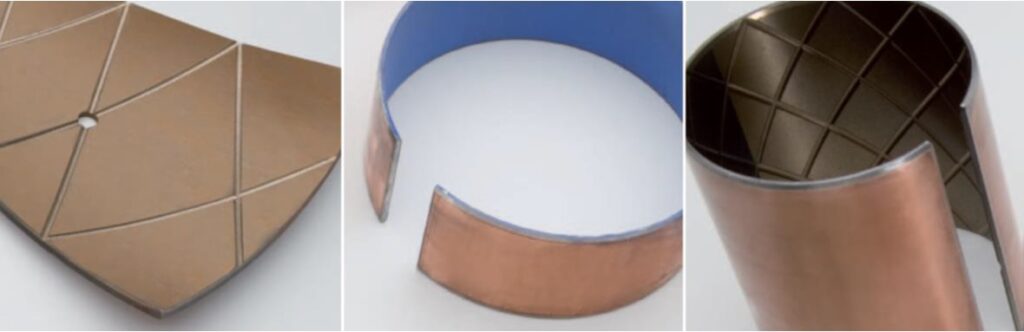

Shapes

deva.bm® is produced as plate and can be easily machined and formed in all kind of shapes, such as plain bearing, spherical shapes, thrust washers, Axial segments, Radial segments and sliding plates.

Applications

deva.bm® is utilized many applications such as:

Water turbine (wicket gate bearings, axial and radial segments) and, injection molding machinery, food and beverage industry machinery, packing machinery, printing machinery, apparatus engineering, shut-off valves, tire molds and many more.

More information

Orange Delta Equipment is the official Federal-Mogul DEVA GmbH sales representative for Singapore, Malaysia, Indonesia, Thailand, Philippines & Vietnam.

Please contact us if you have any questions or specific requirements.